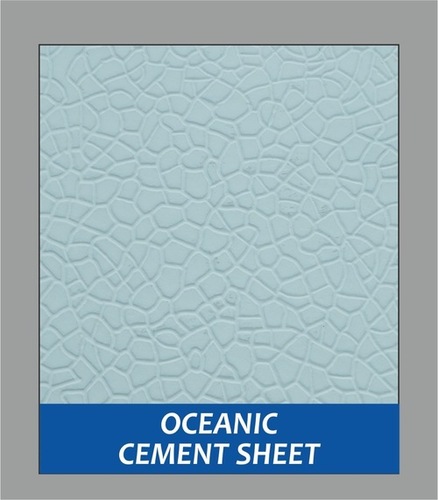

Oceanic Cement Sheet

1010 INR/Piece

Product Details:

- Surface Treatment Smooth Finish

- Height Standard Sheet (Varies by application)

- Features Fire Resistant

- Usage & Applications Roofing, Partition Walls, Cladding, Ceilings

- Technics Autoclaved Process

- Roof Material Cement Fibre Composite

- Material Fibre Cement

- Click to View more

X

Oceanic Cement Sheet Price And Quantity

- 1010 INR/Piece

- 1000 Piece

- Less than 20%

- Class 1 (As per IS standards)

- Termite and Rot Proof

- High

- Easy to Cut, Drill, and Fix

- 1.3 to 1.5 g/cm³

- Stacked and Shrink Wrapped

- Grey

- Good Acoustic Properties

- IS 14862:2000 Certified

- Square Cut

Oceanic Cement Sheet Product Specifications

- Roofing, Partition Walls, Cladding, Ceilings

- Flat Sheet

- Low

- Plain

- Cement Sheet

- Rectangular

- Cement Fibre Composite

- Cement

- 1220 mm

- Autoclaved Process

- Smooth Finish

- Standard Sheet (Varies by application)

- Fibre Cement

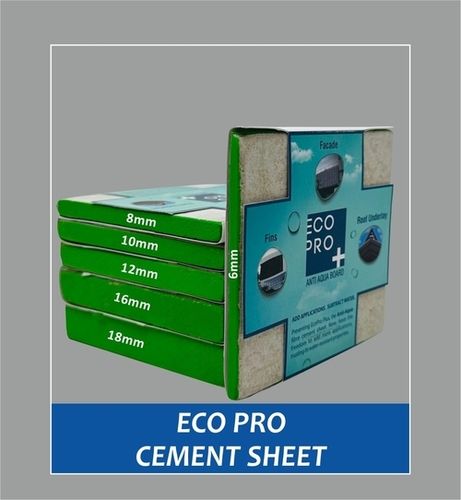

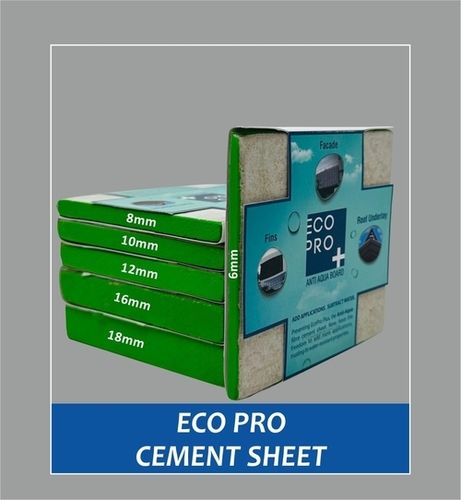

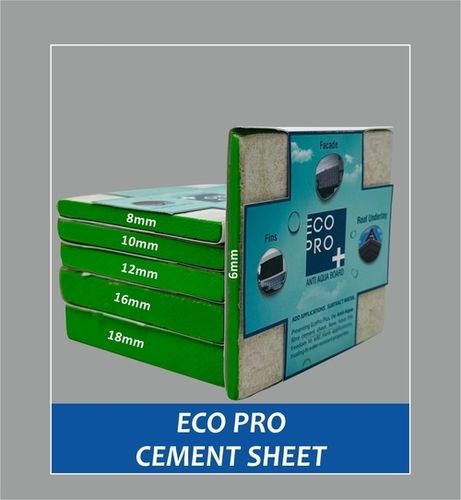

- 6 mm to 12 mm

- 2440 mm

- 8 x 4 feet (Standard)

- Fire Resistant

- Less than 20%

- Class 1 (As per IS standards)

- Termite and Rot Proof

- High

- Easy to Cut, Drill, and Fix

- 1.3 to 1.5 g/cm³

- Stacked and Shrink Wrapped

- Grey

- Good Acoustic Properties

- IS 14862:2000 Certified

- Square Cut

Product Description

Oceanic Cement Sheet

Product Details:

|

Area of Application |

Residential & Commercial, Residential & Commercial |

|

Features |

Corrosion Resistant |

|

Type |

Exposed Grid |

|

Thickness |

8 -12 |

|

Color |

White |

|

Length |

8x4 |

|

Manufacturing Technique |

Cold Rolled |

|

Brand |

Ramco Hilux, Everest |

|

Surface Treatment |

Color Coated |

|

Material |

Asbestos Cement |

Certified Fire and Environmental Safety

Oceanic Cement Sheet delivers exceptional protection, boasting a Class 1 fire rating as per IS standards and resistance to termites and rot. These features make it an optimal choice for both residential and commercial applications where safety and durability are paramount.

Precision and Ease of Installation

Featuring a square cut edge and smooth surface, these cement sheets are easy to cut, drill, and fix, significantly streamlining the installation process. Whether for roofing, ceilings, or partitions, contractors benefit from reduced labor time and a clean, finished appearance.

Superior Acoustic and Thermal Properties

Engineered with good sound insulation and a low heat transfer coefficient, Oceanic Cement Sheets enhance indoor comfort by reducing noise and helping maintain moderate temperatures. This makes them suitable for cladding and partitioning in noise-sensitive or climate-controlled spaces.

FAQs of Oceanic Cement Sheet:

Q: How can Oceanic Cement Sheets be installed in wall or roof applications?

A: Oceanic Cement Sheets are designed for easy installation. With their square cut edges and smooth surface, they can be cut, drilled, and fixed using standard tools. The sheets are typically secured to a metal or timber frame, making them ideal for roofing, cladding, ceilings, and partition walls.Q: What are the primary benefits of using Oceanic Cement Sheets over traditional materials?

A: These cement sheets offer high fire resistance (Class 1, IS 14862:2000), low water absorption, termite and rot proof protection, and outstanding sound insulation. Their durability and ease of installation make them a cost-effective, long-term solution for a wide range of construction applications.Q: Where are Oceanic Cement Sheets commonly used?

A: The sheets are widely used in roofing systems, partition walls, exterior and interior cladding, and ceilings. Their versatility, resistance to environmental threats, and compliance with Indian standards make them suitable for both residential and commercial spaces across India.Q: What is the process behind the manufacturing of Oceanic Cement Sheets?

A: Oceanic Cement Sheets are produced through an autoclaved process, which involves curing fibre cement at high pressures and temperatures. This results in boards with enhanced strength, durability, and resistance to fire, moisture, and environmental degradation.Q: When should these sheets be considered over other building materials?

A: Choose Oceanic Cement Sheets when projects require fire-resistant, termite-proof, and rot-proof materials with good acoustic properties. They are especially suitable for spaces demanding safety compliance and efficient thermal insulation, such as schools, offices, and hospitals.Q: How do the properties of Oceanic Cement Sheets contribute to sustainability?

A: Their termite and rot proof qualities, along with low water absorption and long service life, reduce maintenance and replacement needs. The fibre cement composition also helps in minimizing environmental impact compared to some alternative materials.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Cement Sheet ' category

|

BRAHMANI ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |